HEAT RESISTANT CONVEYOR BELT

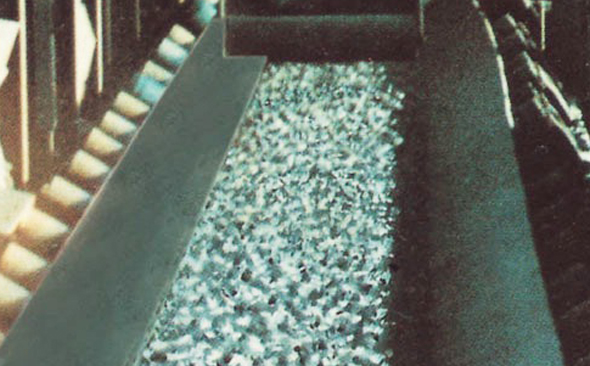

In general it is economical to adopt a heat resistant belt, if the temperature of the material to be carried is over 60oC (140oF). As the damage of the cover depends on the temperature and nature of transported material, the proper selection of a belt to fit particular operating condition is important. Especially the relation of the temperature between the material and belt surface should be considered when selecting the belt.

When transporting material of high temperature, the temperature of the belt surface rises by contact of the material, but on the return journey the heated surface gets cooled naturally by air so that the surface temperature becomes considerably cooler than that of the material. The temperature depends on kind size, temperature, quantity of material to be carried, belt speed, belt length etc. The belt is designed for transporting cement clinker cokes, sintered ores, soda ash, chemicals, fertilizer and etc..

OIL RESISTANT CONVEYOR BELT

Oily material causes the ordinary rubber covers of the belt to swell and peel off, which results in complete breakdown in the conveyor system. This belt compounded of oil resistant quality synthetic rubber had good resistance to the damaging effects encountered when conveying oil contaminated material.

FOOD GRADE CONVEYOR BELT

This belt is made for use where foodstuffs are handled. It is compounded to provide non-toxic, tasteless and odourless properties.

FIRE RESISTANT CONVEYOR BELT

This belt is a prerequisite to prevent fire risks in coal mines where not easily accessible and to reduce maintenance of the conveyors which may be damaged by flame at the blast furnaces of iron works.

COLD RESISTANT CONVEYOR BELT

This belt is made especially for use at the low temperature (-50oC) where a belt with ordinary rubber covers cannot withstand.